Welcome

to

AimExl

We, AimExl India Private Limited, provide comprehensive and customised heat exchange solutions. Our expertise lies in design, development and critical manufacturing. Our extensive product range includes Shell & Tube Heat Exchanger, Air Cooled Heat Exchanger, extruded fin tube manufacturer, aluminium extruded fin tube manufacture, Pressure Vessel, Shell & Fin Tube Heat Exchanger, Plate Heat Exchanger, Double Pipe Heat Exchanger, Composite Air Cooled Heat Exchanger, Skid, Console and finned tubes. We cater to industries like Pharmaceuticals, Oil & Gas, Refineries, Compressor OEM, Fertilizers, Chemicals, Power, Steel, Petrochemicals and more.

Strengths

Innovation

We provide innovative solutions through expertise in process and mechanical engineering

Advanced Manufacturing

Our Manufacturing machineries and processes elevate to cater speedy and high quality equipment.

Project Management

We are committed to achieve 100% on time delivery through efficient project management skill.

Established Products

All our process equipment are the qualitative result of our advanced design data and field experience which delivers desired result and extensive life.

Customer

Support

We are committed to achieve supreme customer satisfaction to our round the clock customer support.

Products

AimExl has a versatile product portfolio for comprehensive heat transfer and process solutions in wide range of sizes and metallurgies for various applications with the complete scope of thermal design, mechanical design, and development.

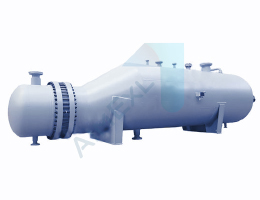

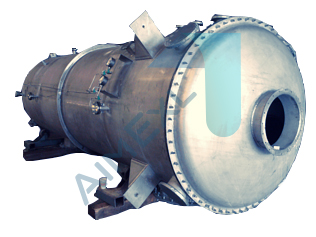

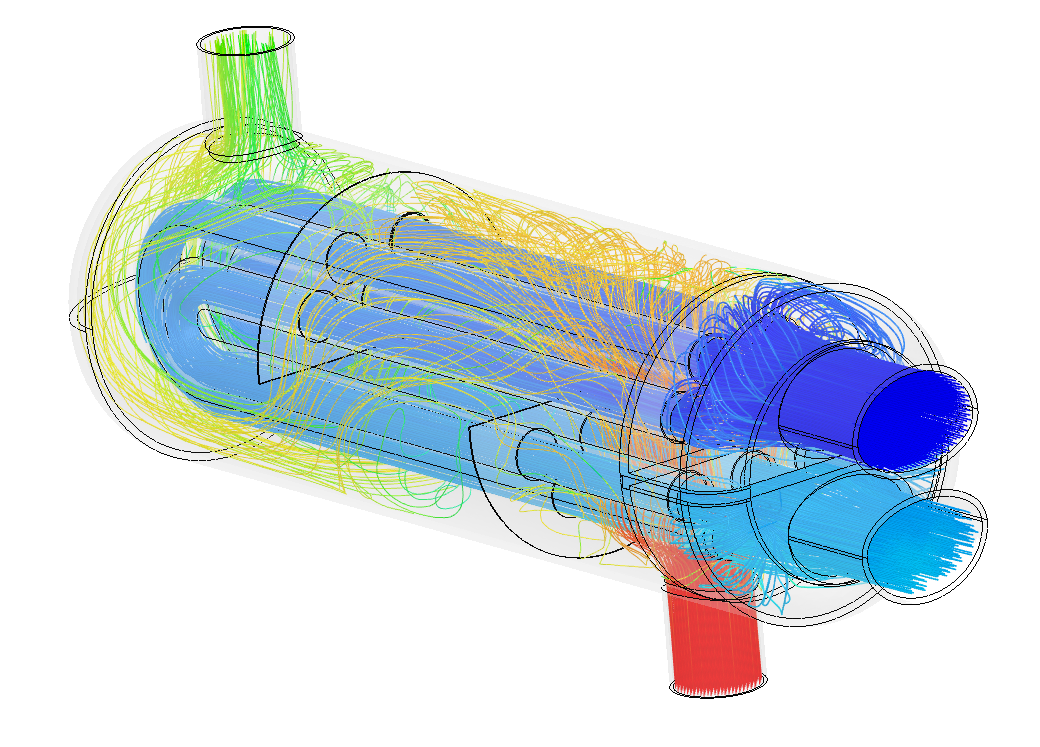

Shell & Tube Heat Exchanger

Shell and Tube Heat Exchanger is a widely used heat transfer solution by industry. Shell and Tube Heat Exchanger consists number of tubes mounted into a cylindrical shell. Heat transfer takes place by indirect cooling between shell side and tube side medium. Shell and tube heat exchangers can be further classified based on the construction, codes, and standards.

ASME & TEMA Type

ASME & TEMA Type Shell and Tube Heat Exchanger

It is widely used heat exchanger in all major industries. This type of shell and tube heat exchanger is designed and manufactured in line with ASME and TEMA standards guidelines.

Shell and Tube Heat Exchangers are widely used in Oil & Gas, Petrochemical, Fertilizer, Pharmaceuticals, and Food Processing industry.

Codes & Standards: ASME SEC VIII DIV I, DIV II, TEMA, ASME BPE, HEI, CE/PED, API 660, IS-4503

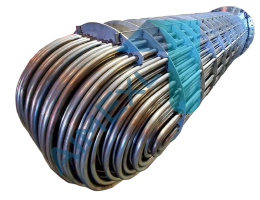

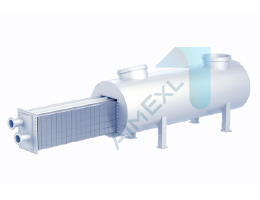

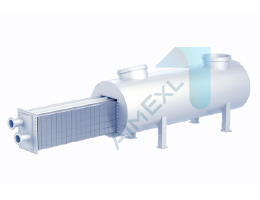

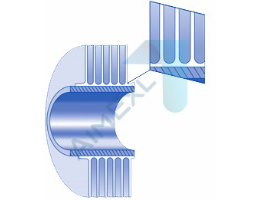

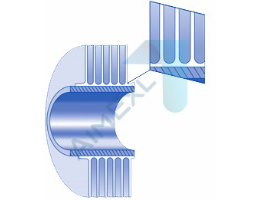

Shell & Fin Tube Heat Exchanger

Shell and Fin Tube Heat Exchanger

Shell and Fin Tube Heat Exchanger is a combination of benefits of Shell and Tube Exchanger & fin tube heat exchanger. It is also known as an extended surface heat exchanger as by using fin tubes we are extending the heat transfer surface area within the Shell. It provides superior cooling at low-pressure drop.

Shell and Fin Tube Heat Exchanger used in compressor industry, air separation plant, fertilizer, refinery, petrochemical, and process industry.

Codes & Standards: ASME, TEMA, PED/CE

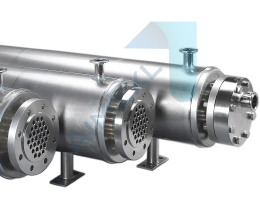

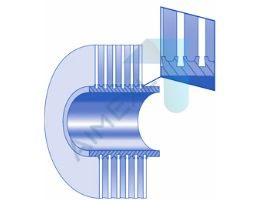

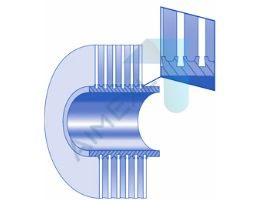

Double Pipe Heat Exchanger

Double Pipe Heat Exchanger

In double pipe heat exchangers, a large pipe with a small pipe inside it concentrically, and all the heat transfer process occurs inside the larger pipe. One fluid flows through the inner of a small pipe, and another fluid is between the two pipes.

Double Pipe Heat Exchanger used as Fuel gas heaters, Lean - rich glycol exchangers, Lean - rich amine exchangers, Lean - rich CO2, Gas coolers, Well stream heaters, Intercoolers, After coolers, Heat Affluent Exchangers.

Codes & Standards: ASME, TEMA

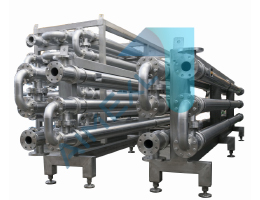

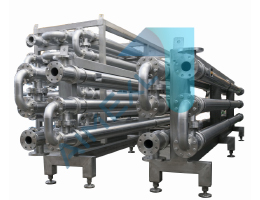

Hair Pin Heat Exchanger

Hair Pin Heat Exchanger

Hair Pin Heat Exchangers truly works on counter-current flow and maximizing the performance when the process requires a temperature crossing. Hair Pin consists of multi-tube bundle into the shell pipe with a removable enclosure. Tube bundle can be Finned Tube, Straight Tube, U Tube, Fixed Tube Sheet, or removable type. Hairpin Solutions are for heating, cooling, condensing, and vaporizing.

Hair Pin Heat Exchangers are widely used in Fertilizer, Oil & Gas, Petrochemical, and Chemical industry.

Codes & Standards: ASME, TEMA, API 663, CE/PED.

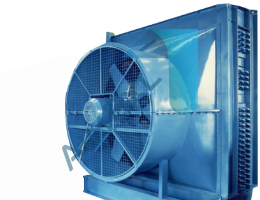

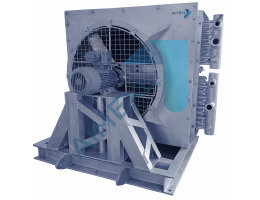

Air Cooled Heat Exchanger

Air Cooled Heat Exchanger is also known as Air Fin Cooler and Fin Fan Cooler. In this type of heat exchanger process medium passes through Tube Bundle and is cooled by ambient air. Air Fin Cooler is frequently used in Petroleum, Chemical, Power, Compressor and other process industry. Air Fin Cooler further classified based on code, standards, and construction.

API & ASME

Air Fin Cooler (API & ASME)

Air Fin Cooler is constructed as per API 661 and ASME SEC VIII DIV 1 & 2. Air Fin Cooler can be known based on construction as Forced Draft, Induced Draft, Horizontal, and Vertical Bundle and fan. The type of fin is selected based on the application and environmental condition. Generally used Fins are G Type (Embedded), L Type (Wrap On), LL Type (Overlapped), KL Type (Knurled footed), and Extruded Type (Bi-Metallic). Air Fin Cooler is popularly selected for a site having water scarcity or high cost of water.

This type of air-cooled heat exchangers are widely used in Oil & Gas, Petrochemical, Chemical, Compressor Industry, and Process Industry.

Codes & Standards: ASME SEC VIII Div1 & 2, API 661

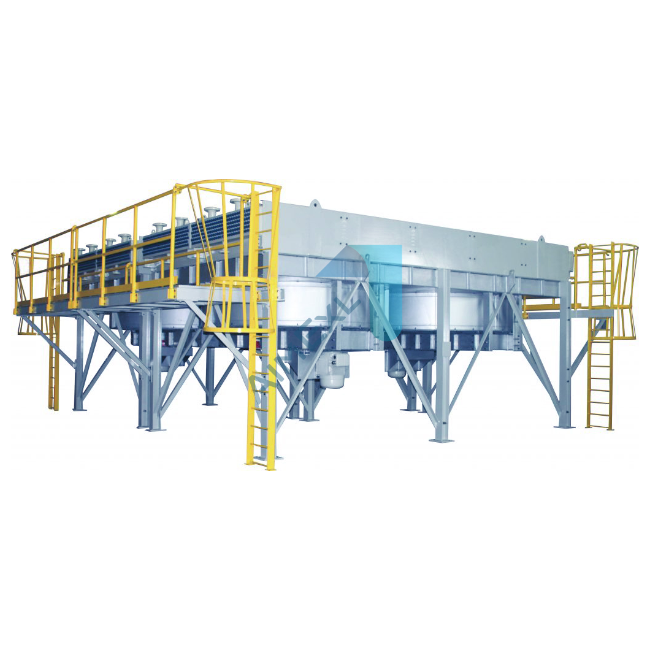

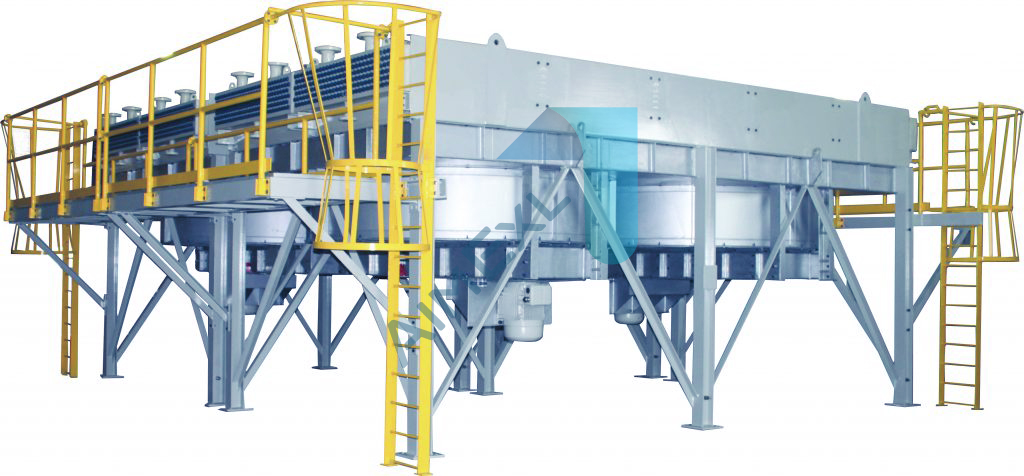

Composite Air Cooler (CAC)

Composite Air Cooler (CAC)

Composite Air Cooler is a type of Air Cooled Heat Exchanger designed to cool multiple process medium by single or multiple fans into one structure assembly. Composite Air Cooler is a specially designed product mainly for the Gas Compressor industry. However, it can be designed for other applications as well. Composite Air Fin Cooler generally consists of Tube Bundle for Gas Cooling (IC1, IC2, AC), Tube Bundle for Oil Cooling (OC), Tube Bundle for water cooling (EJW), and a Tube Bundle for Auxiliary (AUX).

Composite Air Cooler is widely used in Natural Gas Compression for Booster Compressor, Online compressors and Mother Compressor.

Codes & Standards: ASME SEC VIII Div1 & 2, API 661

Pressure Vessel

Pressure vessels are cylindrical and spherical containers used to hold liquids, vapors, and gases at a pressure significantly higher or lower than the ambient pressure. Equipment such as reactors, flash drums, separators, and heat exchangers are examples of pressure vessels. They are widely used in various industries such as petrochemical, oil and gas, chemical, and food processing industries.

Storage Tank & Process Vessel

Storage Tank & Process Vessel

Storage and Process vessels are a broad classification of pressure vessels. These are containers where industrial processes occur, such as mixing and agitation, decantation, distillation, mass separation, and chemical reaction. AimExl can provide solutions for a special purpose pressure vessel with internal cladding, internal complex capping arrangements and other special design configurations as per Industry requirements.

This type of vessel is widely used in Refinery, Petrochemical, Chemical, Pharmaceutical, and Food processing.

Codes & Standards: ASME SEC I, VIII Div1 & 2, ASME BPE, API 510, API 650, API 941, CE/PED

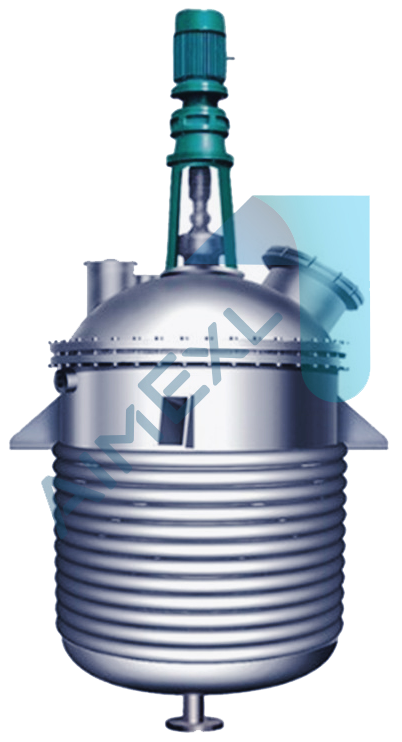

Vessel with Agitator

Vessel with Agitator

Agitators are equipment used in homogenizing media inside a vessel. It works by rotating the impeller at its immersed end at a controlled speed or revolutions per minute (rpm). Agitators are used to perform diverse functions in any industrial plant, which include:

- Blending

- Heat transfer

- Homogenization

- Reactor

- Suspension

- Storage

- Continuous reaction

- Fermentation

- Hydrogenation

This type of vessel is widely used in the Pharmaceutical, Chemical, and Food processing industry.

Codes & Standards: ASME SEC VIII Div. 1, ASME BPE, GMP

Vessel with Limpet Coil

Vessel with Limpet Coil

Vessel with a limpet coil is the pressure vessel with half pipe coil known as a limpet welded on the outer surface. Limpet coil vessels are used to control the temperature of the reactants with the help of heating or cooling media circulated through coils surrounding the main vessel. Limpet coil vessels are generally used by industry as process reactors.

Vessel with limpet coils are used in API, Pharmaceutical, BioProcess, Adhesive, Paint, Cosmetics, Chemical, and Petrochemical industry.

Codes & Standards: ASME SEC VIII Div. 1, ASME BPE, GMP

Plate Heat Exchanger (PHE)

Plate type heat exchanger is a compact type of heat exchanger that uses thin metal plates to transfer heat from one fluid to another fluid. Plates are made of corrugated or herringbone pattern. Each heat transfer plate has gasket arrangements and form two separate channels. Plate type heat exchanger can be further classified based on the construction.

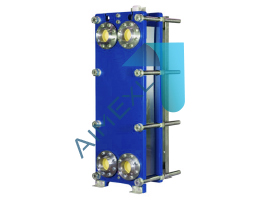

Standard Gasketed Plate Heat Exchanger

Standard Gasketed Plate Heat Exchanger

Gasketed plate heat exchangers are optimizing heat transfer by large surfaces of corrugated plates drawing heat from one gas or liquid to the other. The high efficiency and an outstanding reliability in a compact design. We offer wide range of plate portfolio of Alfa Laval, Sondex, GEA, Tranter, Hisaka, Thermaline, Funke, APV, etc. It provides highest thermal approach, close temperature approach.

Gasketed Plate Heat exchanger has wide application in HVAC, Marine/offshore, Dairy/food/beverage, Sugar, Biogas, Pulp and paper, Heavy, Mining, Petrochemical, Chemical industry.

Codes & Standards: ASME sec VIII, Div. 1, FEA and PED 2014/68/EU (EN13445)

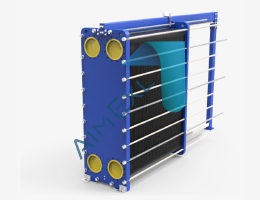

Semi Welded Plate Heat Exchanger

Semi Welded Plate Heat Exchanger

Semi Welded Plate Heat Exchangers are first choice for challenging application that involves high pressure or aggressive media. Our customized Semi Welded Plate Heat Exchanger offer safe operation for hazardous media, high pressure or extreme temperatures that are not suitable for regular Gasketed Plate Heat Exchanger. We offer wide range of plate portfolio of Alfa Laval, Sondex, GEA, Tranter, Hisaka, Thermaline, Funke, APV, etc. It provides highest thermal approach, close temperature approach.

SEMI WELDED PLATE HEAT EXCHANGER has wide application in HVAC, Marine/offshore, Dairy/food/beverage, Sugar, Biogas, Pulp and paper, Heavy, Mining, Petrochemical, Chemical industry.

Codes & Standards: ASME sec VIII, Div. 1, FEA and PED 2014/68/EU (EN13445)

Skid & Console

Skid and Console can be simply put into words as Part of a Process System or Process system mounted on a modularized frame. It involves Static Equipment (Heat Exchangers, Vessels, Compressors, Reactors), Piping, Fittings, Valves, Pumps, Flowmeters, Instrumentation, Insulation, Tubing, etc.

Skid

Skid

A skid or modular process skid is a standalone process system contained within a frame or module including equipment, piping, and instrumentation. Modular process skids are one of the best alternatives to traditional stick-built construction. Project time can be substantially reduced due to modular skid. Overall quality also can be improved due to FAT being performed at the Skid manufacturer.

Skids are widely used in various industries. Skids are known based on the name of process or part of process it represents. Followings are some of the Process skids AimExl offers:

- Chemical processing

- Lubrication Systems

- Wastewater treatment systems

- Metering system

- Filtration system

- Separation unit

- Dosing unit

Codes & Standards: ASME, TEMA, API, GMP

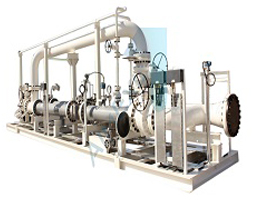

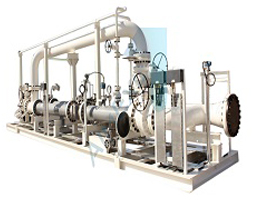

Console

Console

Lube Oil Consoles and Oil systems are used to provide pressurized lubricating oil to various types of industrial rotary equipment. Lube Oil Console is used to supply clean and cool oil to all the bearing points of the system i.e., Turbine system, Compressor system, Centrifugal Pump system, etc. Typically, these lube oil systems include pumps, heat exchangers, filters, controls, and instrumentation. Turbomachinery oil consoles are made as per international standards and customer specifications.

Consoles are widely used in Turbomachinery for Oil & Gas, Petrochemical, Power, chemicals etc.

Codes & Standards: ASME, API 614, ANSI B31.1, B31.11, CE

Finned Tubes

Finned tubes are bare tubes applied with Finning to increase surface area. It increases heat exchange substantially compared to bare tubes. Extruded Finned tubes are widely used in many heat transfer applications. Based on the finning process it is being further classified as G-Type (Embedded), L-Type (Wrap on), LL-Type (Overlapped), KL-Type (Knurled Footed), Extruded Type (Bi-Metallic) Finned Tube.

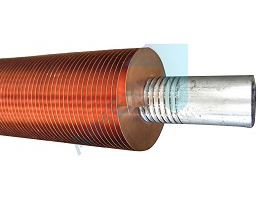

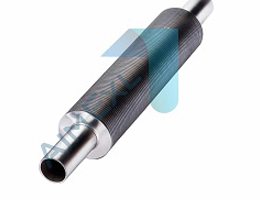

Extruded Fin Tube (Bi-metallic Fin Tube)

Extruded Fin Tube (Bi-metallic Fin Tube)

This fin type is formed from a bi-metallic tube consisting of an aluminum outer tube and an inner tube of almost any material. The fin is formed by rolling material from the outside of the exterior tube to give an integral fin with excellent heat transfer properties and longevity. Extruded fin offers excellent corrosion protection of the base tube.

| Maximum Working Temperature | 310° C |

| Atmospheric Corrosion Resistance | High |

| Mechanical Resistance | High |

| Fin Material | Aluminum |

| Tube Material | Any theoretical limit |

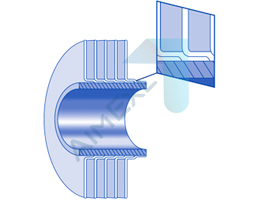

Embedded Finned Tube (G - Type)

Embedded Finned Tube (G - Type)

The fin strip is wound & embedded on a groove and securely locked by closing the groove with the base tube metal. This ensures maximum heat transfer at high temperatures. This ensures that maximum heat transfer is maintained at high tube metal temperatures.

| Maximum Working Temperature | 400° C |

| Atmospheric Corrosion Resistance | Low |

| Mechanical Resistance | Medium |

| Fin Material | Aluminum, Copper, Carbon Steel |

| Tube Material | Any theoretical limit |

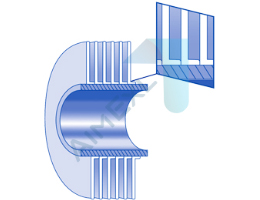

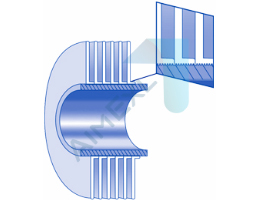

Wrap-On Fin (L – Type)

Wrap-On Fin (L – Type)

The fin strip material is subjected to controlled deformation under tension giving the optimum contact pressure of the foot of the fin onto the base tube thus maximizing the heat transfer properties.

The foot of the fin considerably enhances the corrosion protection of the base tube.

| Maximum Working Temperature | 200° C |

| Atmospheric Corrosion Resistance | Medium |

| Mechanical Resistance | Low |

| Fin Material | Aluminum, Copper |

| Tube Material | Any theoretical limit |

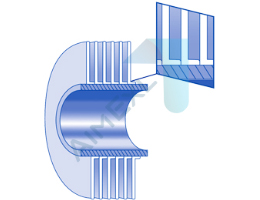

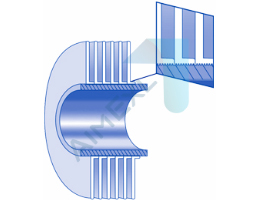

Overlapped Footed Fin (LL – Type)

Overlapped Footed Fin (LL – Type)

Manufactured in the same way as the 'L' finned tube type except that the fin foot is overlapped to completely enclose the base tube thereby giving excellent corrosion resistance. This type of finned tube is often used as an alternative to the more expensive extruded type fin in corrosive environments.

| Maximum Working Temperature | 220° C |

| Atmospheric Corrosion Resistance | High |

| Mechanical Resistance | High |

| Fin Material | Aluminum, Copper |

| Tube Material | Any theoretical limit |

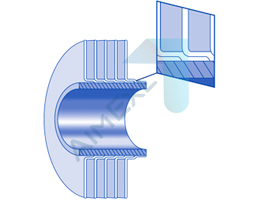

Knurled Footed Fin (KL – Type)

Knurled Footed Fin (KL – Type)

Manufactured exactly as the 'L' finned tube except that the base tube is knurled before application of the fin foot. After application, the fin foot is knurled into the corresponding knurling on the base tube thereby enhancing the bond between the fin and tube, resulting in improved heat transfer characteristics.

| Maximum Working Temperature | 260° C |

| Atmospheric Corrosion Resistance | Medium |

| Mechanical Resistance | Medium |

| Fin Material | Aluminum, Copper |

| Tube Material | Any theoretical limit |

Metallurgical Capabilities

AimExl have capabilities to manufacture Heat Exchanger in wide range of sizes and metallurgies for various applications with complete scope of thermal design, mechanical design and drafting. Below are the commonly used industry known variants

Stainless Steel - SS

Austenitic

(SS 304, 304L, 316L, 310, 321)Ferritic & Martensitic

(SS 409, 410, 420, 430)Super Austenitic

(SS 904L, 254 SMO)Duplex

(UNS 31803 & 32205)Super Duplex

(UNS 32750 & 32760)Hyper Duplex

(UNS 33207 & 32707)Urea Grade Steel

(310MoLN, 316 mod)Carbon Steel - CS

Fine grain steel / Normalised

CS Grades

(SA 516 GR 60/70, SA 285,SA 179, SA 192)LTCS Grades

(SA 537 CL 1/2,SA 334 GR 1/3/6)P-No. 1

(Gr. Nos. 1,2,3)P-No. 4

(Gr. Nos. 2)P-No. 9B

(Gr. Nos. 1)Clad Constructions

(i.e. CS + SS, CS+LAS)Non-Ferrous-NF

Copper

Cu-Ni 90/10

Cu-Ni 70/30

Admiralty Brass

(SB 111 C44300)Naval Brass

(SB 171 C46400, C46500)Aluminum-Nickel-Bronze

(UNS C95800)Low Alloy Steel-LAS

0.5 Mo

(Grade 2)1 Cr – 0.5 Mo

(Grade 11)1.25 Cr – 0.5 Mo

(Grade 12)2.25 Cr – 1 Mo

(Grade 22)Clad Constructions

(i.e. LAS + SS)Industry We Serve

Blogs

What is Heat Transfer?

Plate type heat exchanger is a compact type of heat exchanger that uses thin metal plates to transfer heat from one fluid to another fluid. Plates are made of corrugated or herringbone pattern. Each heat transfer plate has gasket arrangements and form two separate channels. Plate type heat exchanger can be further classified based on the construction.

Building a more competitive business sectors

New analytic tools can help manufacturers in labor-intensive sectors.

Building a more competitive business sectors

New analytic tools can help manufacturers in labor-intensive sectors.

Building a more competitive business sectors

New analytic tools can help manufacturers in labor-intensive sectors.

Building a more competitive business sectors

New analytic tools can help manufacturers in labor-intensive sectors.

What is Heat Transfer, & How does it work?

New analytic tools can help manufacturers in labor-intensive sectors.

What is Heat Transfer, & How does it work?

Would you like to know how heat transfer works and what exactly it is? This article will break down how heat transfer works and give an overview of the different types of heat transfer.

What is Heat Exchanger?

Heat exchangers are used to transfer heat from one medium to another. These media may be a gas, liquid, or a combination of both.